The part responsible for shaping the ceramic tiles’ face and backside, It consists of two types: the upper punch which is Installed on the magnetic upper plate and the lower punch which is located in the die box’s cavities and fastened by the magnetic blocks, either one of them can Shape the face Or backside of the tiles depending on the type of the mould used (Entering mould, Mirror Mould, etc…)

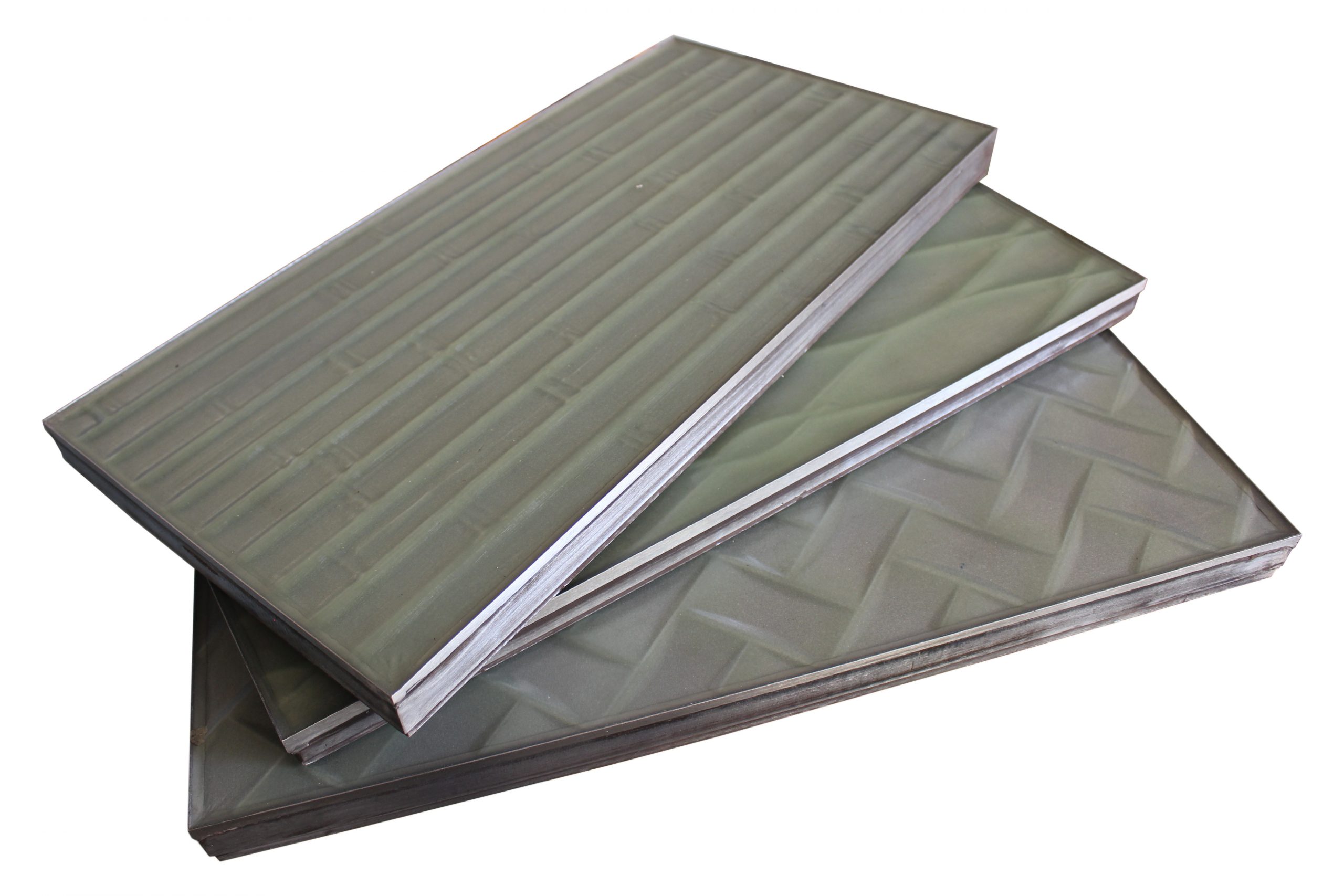

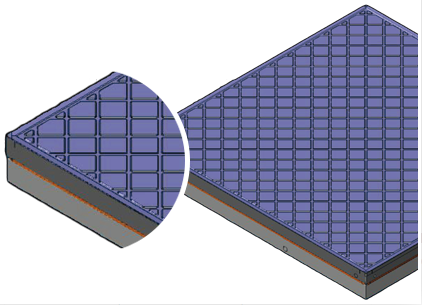

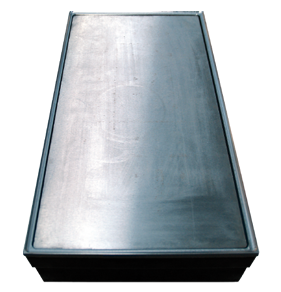

Traditional punches

A punch with a simple design, its depth varies from 1.6:2 mm and filled with resin that varies in thickness from 0.6:1 mm.

Isostatic punches

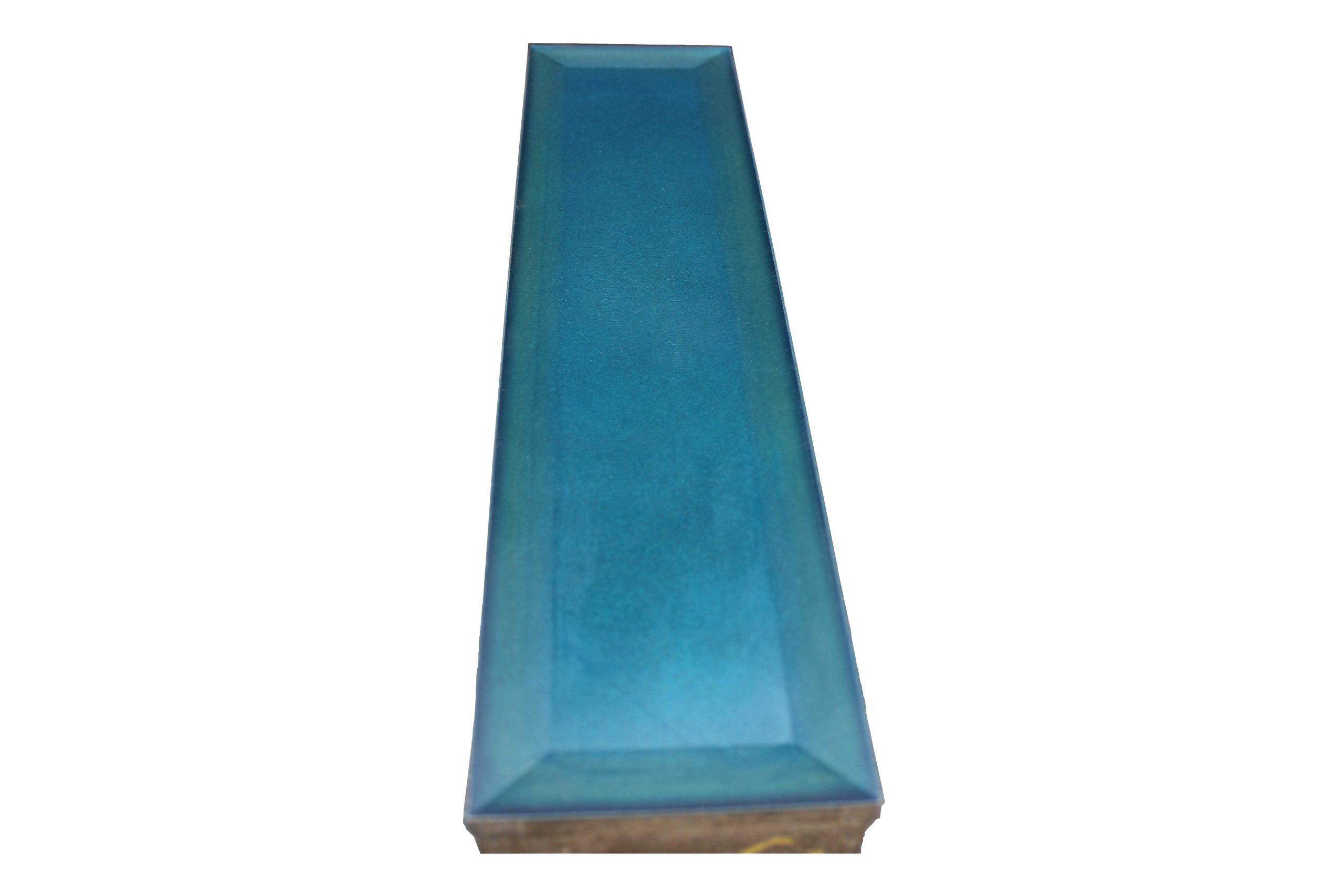

Isostatic punch(Slot):

Either that the slot is part of the punch’s body (the old method), Or to be a metal grid that’s fastened to the punch with screws, the new method is easier to manufacture but surprisingly is relatively lower in compensation than the first

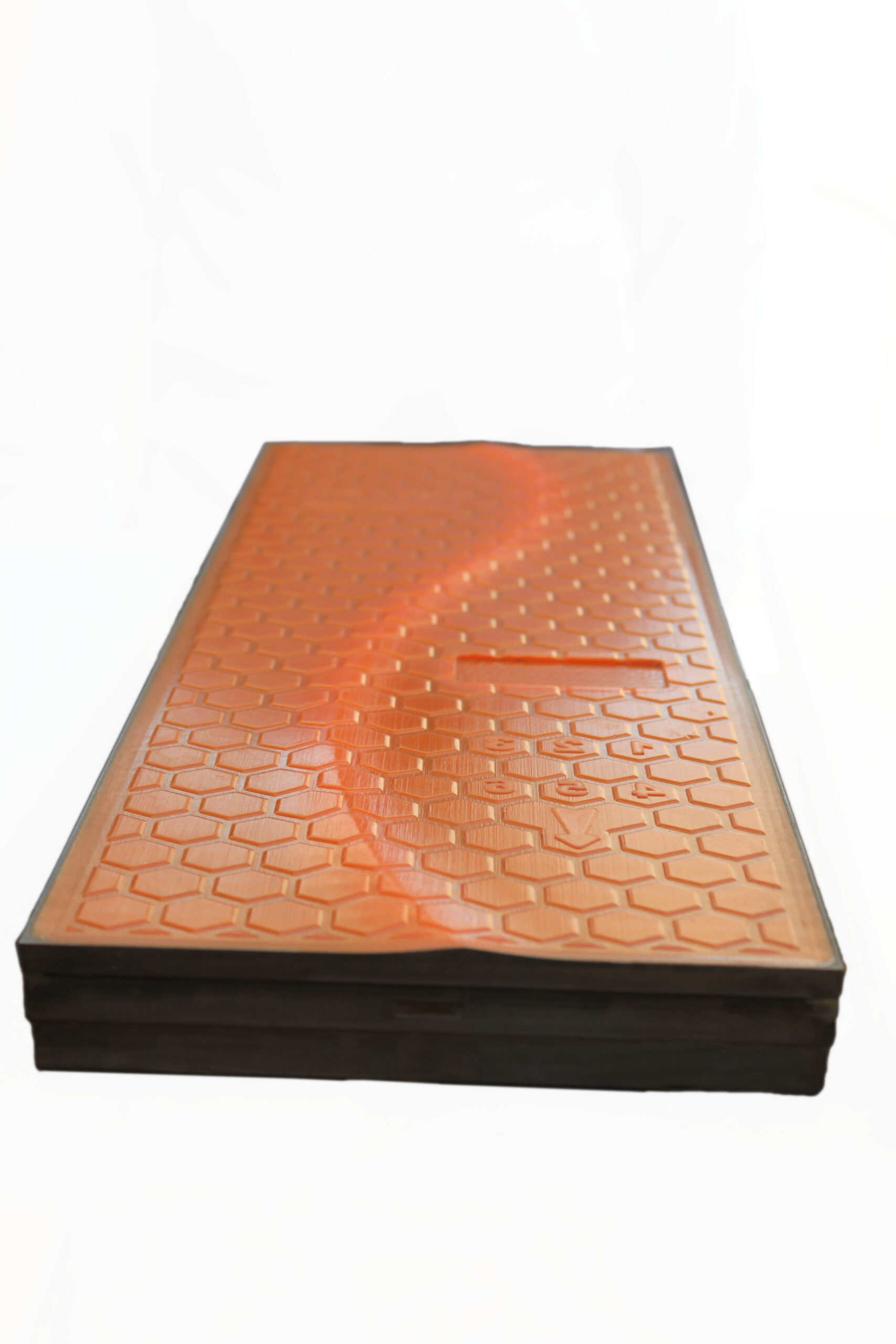

Self-Compensating Punches

Also called the spanish method, It’s prefered to use this type to cure the “shadow effect” flaw.

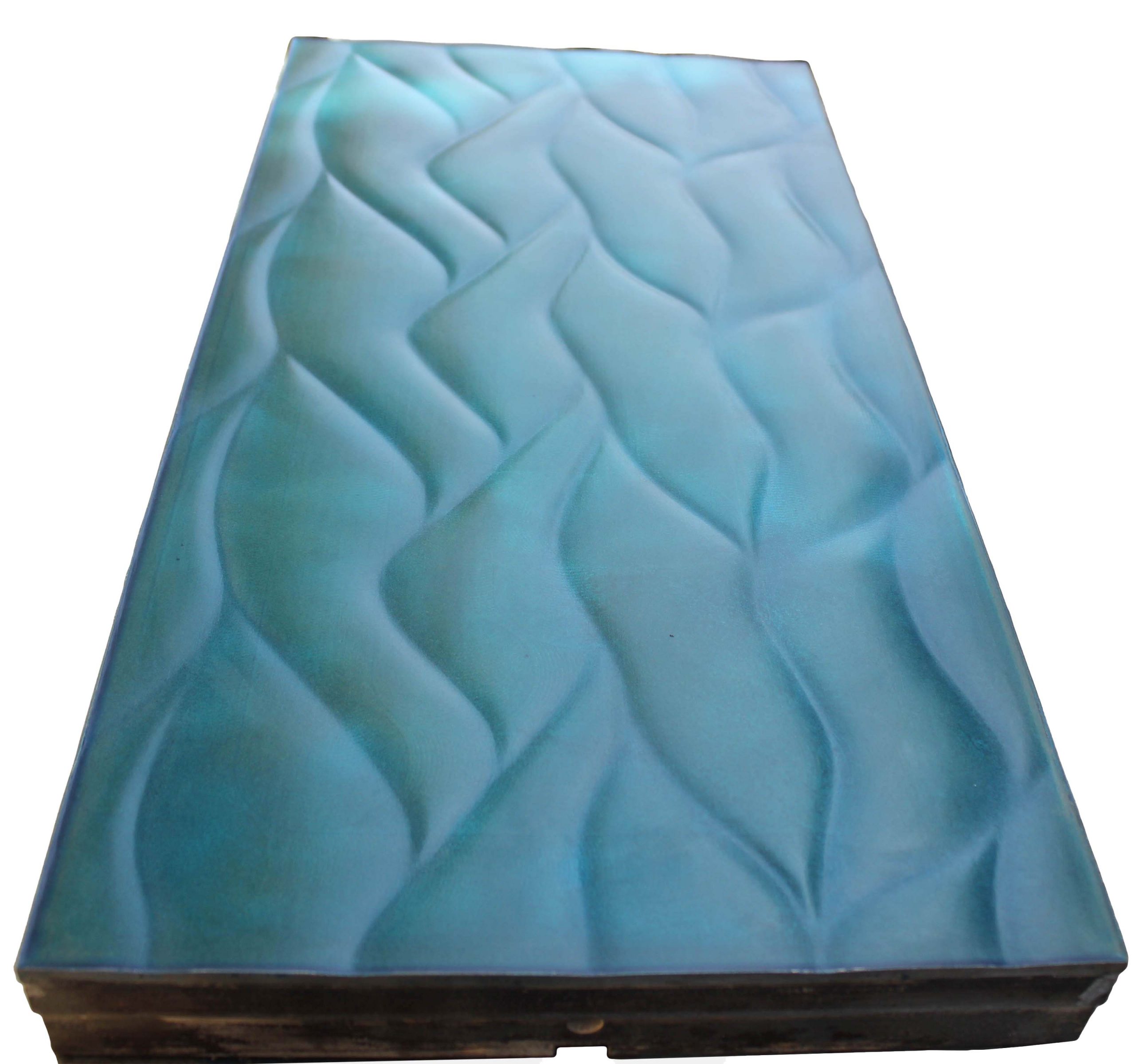

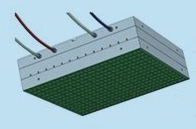

Isostatic Punches (grids):

Preferred for the manufacturing of porcelain tiles,Usually made of caoutchouc.

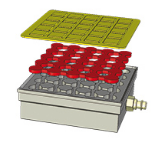

Isostatic Punches (Pistons):

The oldest type that’s no longer used, Consists of a large number of pistons under the resin placed regularly over the area of the punch, complicated and costly to manufacture and maintain.